Первый слайд презентации: ADVANCED TECHNOLOGIES AND THE FUTURE OF WELDING

Module 5

Вакуумная камера, летательный аппарат, источник тепла, Космический корабль, открытый космос, солнечная энергия, Компьютерное моделирование, ручной инструмент, банк данных, Улучшенный материал (материал с улучшенными свойствами). 3

Слайд 4: 2. Read the text again and say what events relate to the past, the present the future. Fill the table. Some examples are given

The past The present The future verifying the possibility of thermal-cutting and welding in space testing in a flying laboratory completely new methods of nondestructive testing and diagnosing welded structures 4

Слайд 5

On Oct. 16, 1969, astronauts performed the world's first welding and cutting experiment in a depressurized compartment. In flight aboard the Soyuz 6 spaceship, they tested three welding processes with a semiautomatic Vulkan unit (see Figure below): consumable electrode arc in vacuum, low-pressure plasma, and electron beam welding. They studied how to weld aluminum and titanium alloys and stainless steel. They verified the possibility of thermal-cutting these materials and investigated the behavior of molten metal and features of its solidification. This experiment convinced experts that they could use automatic welding to produce permanent, tight joints in space. They expanded this work with a series of investigations conducted under short-time microgravity conditions in flying laboratories and space simulation test chambers. In 1973 NASA experts conducted a flight experiment with electron beam cutting, brazing, and welding in the Skylab orbital station. Space welding technologies have advanced since then. In-space repair and construction of space facilities and their equipment and instrumentation were defined in the 1980s. Another major area identified was producing advanced materials in space with new or improved properties using different heat sources. Over the years scientists and specialists had to address construction of various experimental space vehicles, namely, orbital and interplanetary stations, radio telescopes, antennas, reflecting shields, and helio power generation systems - in outer space. In addition to the original problems of assembly and erection in outer space, as well as their view of how long these vehicles would be used and increases in the vehicles' weight and dimensions, specialists focused more attention on preventive maintenance and repairs. 5

Слайд 6: 3. Say if the following is true or false

1. The world's first welding and cutting experiment was carried out in the outer space. 2. Thermal-cutting of aluminium, titanium alloys and stainless steel is impossible in space. 3. Only automatic welding is of importance for aerospace. 4. A flight sample of an onboard electron beam hand tool was produced as a result of series of experiments. 5. Space welding is used for maintenance and repair purposes. 6

Слайд 7: 4. Translate the following sentences into English

1. На борту космического корабля исследователи изучали поведение расплавленного металла и особенности его кристаллизации в условиях кратковременной микрогравитации. 2. Технологии космической сварки шагнули далеко вперед. 3. Одна из задач, решаемых с помощью сварки в открытом космосе, – профилактическое обслуживание и ремонт оборудования космического корабля. 4. Разнообразие используемых материалов и невысокая энергоемкость оборудования являются решающими факторами, обусловливающими возможность использования сварки в открытом космическом пространстве. 5. Дальнейшее освоение космического пространства потребует усовершенствования практически всех видов сварочных технологий, а также резания, пайки и нанесения покрытий. 6. Специфика используемого на космических кораблях оборудования обусловливает необходимость использования, прежде всего, ручной сварки при частичной автоматизации процесса. 7. Электроннолучевой ручной сварочный аппарат прошел успешные испытания на орбитальном комплексе в условиях открытого космоса. 8. Использование новейших материалов в следующем столетии потребует разработки совершенно новых технологий получения неразъемных соединений. 7

Слайд 9: 5. Describe Orbital welding by completing the following sentence

1. The term Orbital comes from the Latin word ORBIS and means …. 2. The Orbital Welding is a process in which an arc travels …. 3. By category it belongs to …. 4. It is practiced only with …. 5.Orbital-welding is presently used in such areas as …. 6. It is used to produce …. 7. The basic rules for this process are …. 8. Absolute tolerances in Orbital-Welding Process are important because …. 9. Wall-thickness of 4 mm is possible …. 10. Joint preparation includes …. 11. Orbital-multi-pass-welding is rather expensive and its use is only justified when …. 12. Filler-wire is necessary to use only …. 9

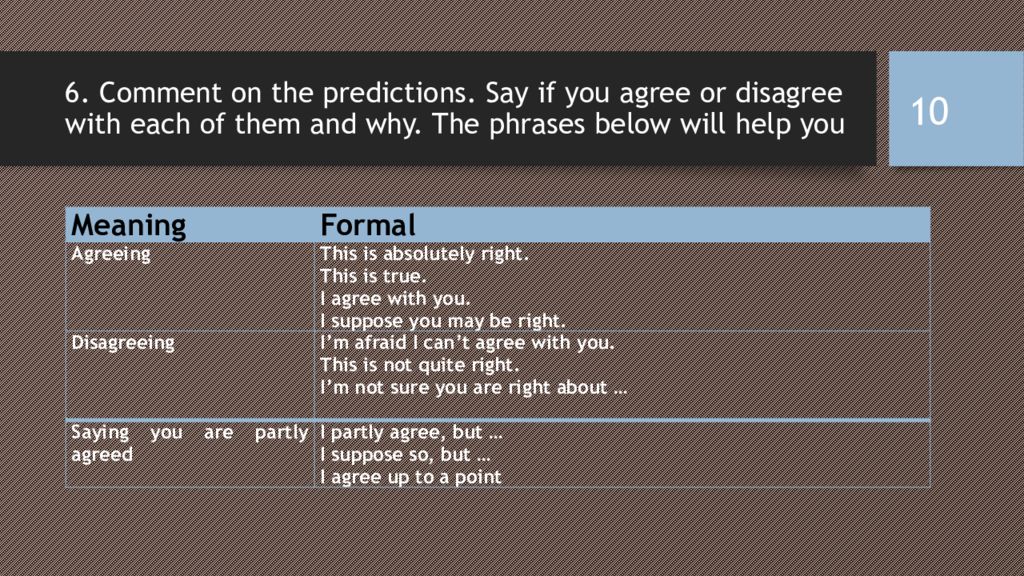

Последний слайд презентации: ADVANCED TECHNOLOGIES AND THE FUTURE OF WELDING: 6. Comment on the predictions. Say if you agree or disagree with each of them and why. The phrases below will help you

Meaning Formal Agreeing This is absolutely right. This is true. I agree with you. I suppose you may be right. Disagreeing I’m afraid I can’t agree with you. This is not quite right. I’m not sure you are right about … Saying you are partly agreed I partly agree, but … I suppose so, but … I agree up to a point 10